Toll Free (519) 659-2832

Mon - Fri 8:00AM - 5:00PM

In a busy warehouse the loading dock is part of the heartbeat of operations. Often overlooked, the loading dock is an essential part of highly productive, safe, secure, and efficient logistics operation. Different types of loading dock levelers stand up better in different applications. Knowing and implementing what is best for your facility can save you significantly and quality Rite-Hite equipment will deliver the lowest lifetime ownership costs.

Loading dock levelers play an essential role in the logistics and warehousing industry by facilitating the safe and efficient transfer of goods between trucks and building floors. With a diverse fleet of delivery vehicles on the road, mismatched dock levelers could lead to delays and negatively impact client satisfaction.

Learn about the different types of loading dock levelers that will drive your search for the right solutions in loading dock equipment.

A loading dock leveler is a mechanical device created to connect the space between a loading dock and a truck, essentially a bridge between trail and the building floor. These levelers are typically mounted within a loading dock pit and come in various forms. When a truck backs up to the dock, the leveler is raised and a lip extends outward to connect securely with the truck bed. This creates a smooth transition that accommodates variations in height between the dock and the trailer, making it easier for forklifts, pallet jacks and personnel to move goods safely.

Loading dock levelers include the following key components:

Other benefits of Rite-Hite loading dock levelers include:

Here’s a detailed overview of the different types of dock levelers commonly used in loading dock operations. We’ll compare the differences between an edge of a dock leveler versus a pit leveler, which are the two main categories of loading dock levelers. Plus, we’ll discuss how specialty options are customized to meet individual warehouse needs.

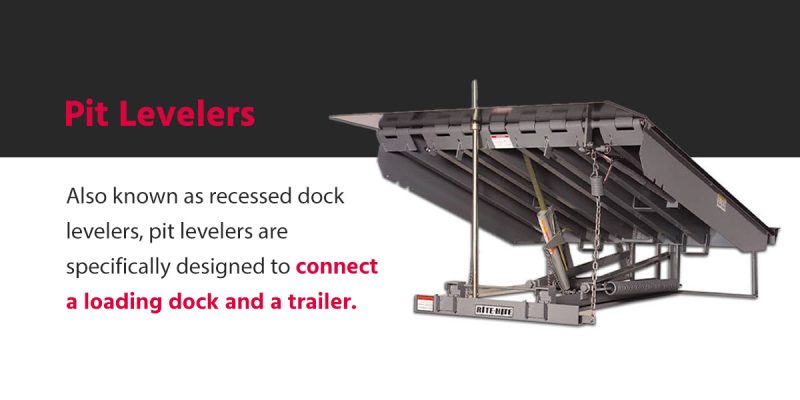

Also known as recessed dock levelers, pit levelers are specifically designed to connect a loading dock and a trailer. They are installed in a recessed concrete opening at the dock door to provide a seamless transition for loading and unloading operations. This type of leveler is particularly versatile and is engineered to accommodate a wide range of load capacities and trailer heights.

Pit levelers have various activation systems. The most common types include:

A specialized type of dock leveler, vertical dock levelers are stored upright when not in use. This design helps maintain temperature control and cleanliness in environments requiring stringent hygiene standards, such as food service applications. It minimizes energy loss and prevents debris from entering the pit.

Vertical levelers are used as part of drive-through dock design which allows the trailer to back into the dock with doors closed before the dock attendee opens from the inside of the building. This is ideal from a safety (less boots on the ground in the drive approach) and security (reducing theft) perspective. Vertical levelers are growing is usage beyond food and pharma manufacturing for this very reason.

Edge-of-dock (EOD) levelers are compact devices typically mounted directly to the dock face or to the exterior wall of a building. They are cost-effective options for facilities without existing dock pits. Unlike pit levelers, EOD levelers offer a limited vertical operating range, meaning they’re best suited for applications where the transport vehicles are consistently the same and bed height is close to the dock level.

The compact design of EOD levelers allows for easy installation and operation in smaller loading areas. They also provide a smoother transition for foot traffic, pallet jacks, and forklifts, mostly used in low-volume loading bays.

EOD levelers can be mechanically or hydraulically operated. Mechanical EOD levelers require operators to manually pull the lip and ramp into position. Hydraulic EOD levelers are activated by pressing a button, providing ease of use and reducing manual effort.

Specialty dock levelers are designed to meet specific operational needs that standard dock levelers may lack. They have unique features and configurations tailored for distinct uses, such as handling oversized cargo or functioning in specialized environments.

Here are some examples of specialty dock levelers:

If you have space constraints, budget limitations or different operational needs, you have several loading dock alternatives for loading and unloading freight. Each option has its own advantages and considerations to ensure safety and efficiency in operations:

Although many alternatives exist, loading dock levelers can significantly enhance operational efficiency in a warehouse. They’re essential pieces of equipment in loading dock operations. Each type of leveler comes with varying safety features that suit your specific dock loading and warehousing needs.

Arbon Canada has dock levelers that offer you many advantages. Our Rite-Hite® levelers are easy to use and include several advanced safety features and the most robust design in the industry.

Get in touch with our team to learn which dock loading leveler is suitable for your application.